STAGE 2/4

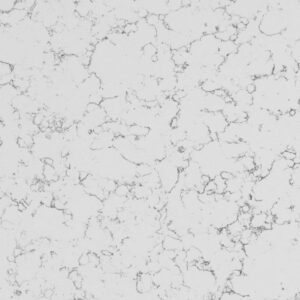

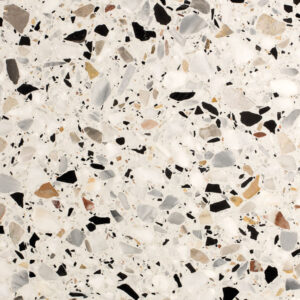

Any terrazzo design follows a strict recipe with precise ratio between stone granules, chips, binders and other ingredients.

A.

Mixing.

Components are loaded into large containers with a funnel chamber, so they can be

measured and mixed in following the terrazzo recipe. The process is fully automated and precisely navigated from the control room.

measured and mixed in following the terrazzo recipe. The process is fully automated and precisely navigated from the control room.

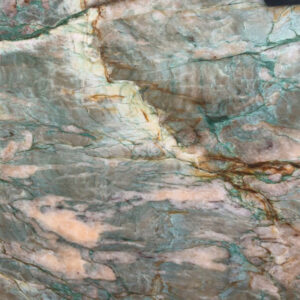

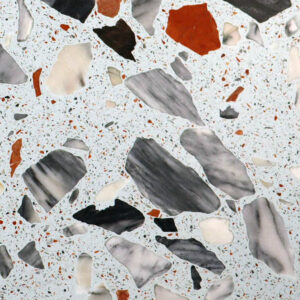

B.

Moulding.

The ready mixture is vibrated in a vacuum to let it settle and to remove any air bubbles. It is

then poured into large, standard-sized metal moulds and baked in an oven at 130ºC.

Terrazzo block being removed from it's mould.

C.

Blocks are left to cure outside.

Curing.

The blocks are cured for 28 days, slabs - for 2 weeks. This allows the cement in the mixture to

reach full strength.

reach full strength.

Terrazzo block, fresh out of the oven.

Dedicated team for Techinical and Design consultation