How can the terrazzo industry support more sustainable practices?

As an established supplier of architectural stone, terrazzo and porcelain tiles, I believe that designers, particularly engineers and architects, can have a lot of influence on sustainable design and I am keen to learn what route we should take to make that happen.

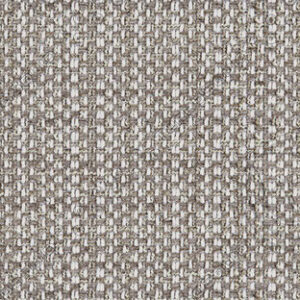

My own sustainability journey, and that of many, began around the mid-nineties. While working for Interface we were told that we were faced with some stiff challenges, such as for every lorry load of finished carpet goods, we were left with 7 lorry loads of waste…

Then, when I started working with hard finishes such as porcelain tiles, I was facing 100-metre-long ovens fired at between 1,200 and 1,400 degrees C to turn pressed or rolled raw materials into porcelain tiles. Although less production waste and very large production runs, we were still faced with some major challenges. I quickly realised that the devil was very much in the detail and understanding the details of each material was key, with textiles and porcelain a sustainable process and source of energy was essential.

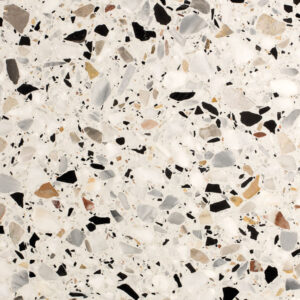

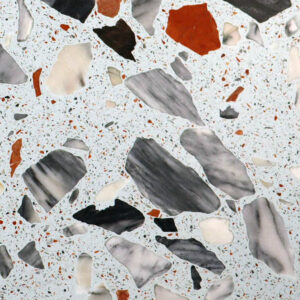

With stone how it was quarried and with terrazzo, I’ll never forget what an inspector said after a factory visit for some major airport projects… “You basically use gravity to take quarry waste into a clever machine that adds either a little cement or resin to turn rubble into blocks the size of a small van, you leave them to cure next to the Valpolicella for a few weeks and then cut them into whatever shape we need and if it fashions out it offers us a screed which we can use for more temporary finishes like carpet etc, at worst it’s a screed that uses a lot less cement that our standard screeds..”

So, the big question for manufacturers, architects and designers is how can we support more sustainable practices? When agreeing budgets, how should we prioritise? How can we help a construction professional identify a material which is less damaging to the environment? Is it of more value to the planet for a factory to spend tens of thousands of pounds on inspections and related certification, like our EPD? Or would that money be better spent on R&D or photovoltaics? With the latter we can use the sun to power our machines, the former, perhaps generate more orders? Truth is at present we have to have both.

What I find reassuring, is that our group of factories, mostly family-run and based mainly in Northern Italy, are proud of their quality, which is also guaranteed by stringent European Norms, from how materials are sourced and how waste is managed. Rules around responsible sourcing, such as child labour, transport and packaging are implied as they have rules implemented by inspectors who randomly check all is in order. I sometimes wonder why we need to invest so much effort and cast in material-specific certification and why don’t we see more official guidelines on which materials to use in construction, should this not be logical for a construction professional?

Talking specifically to our terrazzo production guys in Italy, they operate a very similar system to the wine DOCG system. Not only does the origin of the raw materials have to be demonstrated, but we also have random unannounced inspections, where they take samples of production waste to control that it contains what is declared and where the minimal production waste is disposed of. In short not only are we taking stone from quarries, but we are also replacing it with manufacturing slurry and marble leftovers, which in a few million years will allow the planet to produce a new type of marble. What I am trying to say is, why do we need further material-specific environmental certification, when there are already very stringent controls in place policed by governments, for policing quality and production waste? Shouldn’t the energy (excuse the pun) be pumped into making the system we have more efficient, rather than adding a layer of bureaucracy which adds cost and confusion?

Back to my earlier point, I would be keen to hear the views of designers on how to promote more sustainability. Was that inspector I mentioned ahead of his time in taking an environmental initiative or do we need more regulations like the DOCG system to ensure that companies do their bit to save the planet?

This article is also published on our LinkedIn page: https://www.linkedin.com/pulse/think-piece-sustainability-more-docg-less-epd-in-opera-group-azjxe